Seneca History: the Past

Ryan, the founder of Seneca Woodworking here. It’s hard to believe we’ve been in business for a decade…What a crazy journey it’s been! I thought this would be a good opportunity to share a bit of our story and share what it took to get here, where we are now, and finally give a sneak peak at the future, so over the next few days I’ll share that story with you here..

The past.

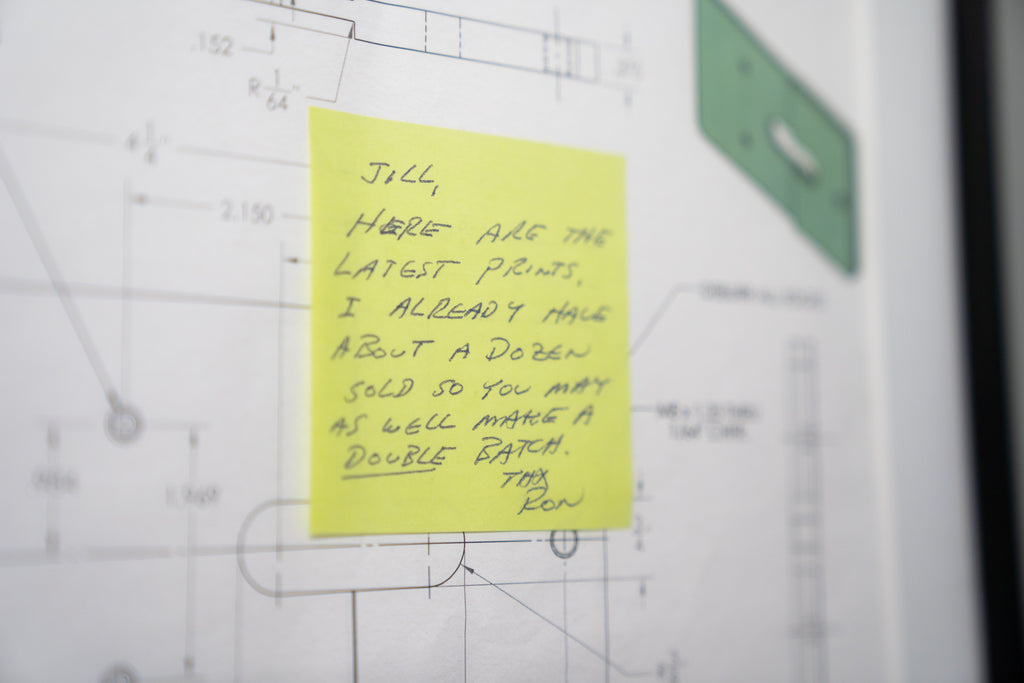

The story of Seneca Woodworking really starts with the story of my Dad and our first product: the Domiplate. My dad has been a lifelong tinkerer, inventor and someone who’s gifted with anything mechanical; As a kid I grew up spending weekends playing with tools and building things in his shop and getting my footing as a “maker” spending time across many disciplines; woodworking, metalworking, electronics, etc. Sometime around 2007 as he was winding down for retirement, he started upgrading the woodworking tools in his shop, adding a lot of Festool tools and spending a lot of time talking about his woodworking passion on several of the Festool related groups and forums. This led to the invention of the “Domino Shoe plate” (which was quickly renamed the Domiplate” ) in 2010. After showing the jig on the forums and finding out others wanted their own, he had a local machine shop produce a small run of 20 pieces of the tool to sell to others on the forums. These 20 pieces quickly sold out, causing him to reorder “a double batch” from the same shop, which also sold out just as quickly. This momentum looked like we might have an actual business, so late in 2011 I created Seneca Woodworking, then in February of 2012 we opened our ecommerce store!

At the time the Domiplate was a bare aluminum plate. People who bought it had to add their own knobs and screws, and most even wrote on it with a sharpie to indicate which side was which. I realized this “DIY” tool could be better, so, I had the Domiplates anodized, then laser engraved with our logo and dimensions, and I sourced a proper knob and mounting screws to make the Domiplate into a polished product.

There was no shortage of problems to solve, so Dad and I kept creating other tools. We created our Parallel Guide System, and then our Small Mortise Kit. For the first few years, I ran the business by myself from my apartment: my spare bedroom became a warehouse, and I added a laser engraver and 3d printer to my main living area.

I started getting weekly deliveries from our cardboard box supplier. I’m pretty sure my UPS driver didn’t love carrying them up the stairs to my second story apartment, but to his credit he never complained.

My spare bedroom “warehouse” quickly filled up with finished goods, and the industrial equipment motif wasn’t the best look for a dining and living area, so it was clear we were outgrowing the space. Things finally came to a head one day while in the middle of a torrential downpour I got a call from a Freight delivery company…letting me know he had a pallet of cardboard boxes for me. Apparently our shipping supply order was larger than they would ship via UPS, and the company had upgraded our order to LTL freight without my noticing. The truck driver was ready to dump our pallet on the street… but I convinced him to maneuver the truck into the apartment’s back parking lot, where I proceeded to unwrap the pallet and sprint into the apartment with the various bundles of boxes before they could get fully soaked in the rail. It was time for an upgrade.

To be continued….